Our philosophy

Working the soil is particularly important; the estate abandoned chemical weeding a long time ago out of respect for the environment, mainly to protect the water resource and the micro-organisms in the soil.

Using a modern and high-performance straddle tractor, we earth up the vines every winter, which protects them from extreme cold, severs the superficial roots, buries the weeds (natural green manure) and drains the plots to avoid compacting.

In the spring, we carry out the unearthing and harrowing, and cut the grass as it comes up using an inter-row hydraulic trimmer. In total, then, we work the soil, passing through the vines six or seven times over the course of the year.

Manual work remains our principal activity and begins with pruning, which is one of the most important operations for the sustainability of the plant and for the quality of the grapes; it is often what determines the yield of the vine.

Single Guyot pruning is carried out taking care to leave only seven buds per vine. We maintain this pruning method by removing the shoots at the foot of each vine; this is the disbudding or shoot thinning in early May when the vines are budding.

We also make sure to remove the double buds that grow on the vine, so that only seven branches remain. The next step is to train the vines, which is also very important because it avoids the accumulation of vegetation that would prevent the aeration of the grapes, which could promote botrytis.

If the crop of grapes is too abundant (with up to fifteen bunches per vine), a green harvest is carried out after fruit set with the aim of leaving only seven to eight bunches per vine, a sufficient quantity to obtain a satisfactory yield of around 40 hectolitres per hectare.

Green harvesting is carried out to optimise maturity and the concentration of phenolic compounds.

The vines are topped three or four times by machine, so that the young shoots that can exhaust a vine are removed; the straddle tractor can then pass more easily, facilitating ploughing and plant protection treatments.

It is indeed necessary to intervene against parasites: to this end, we follow the advice provided by the plant protection service and the Chamber of Agriculture. The interventions are reasoned and reasonable: we observe the vines regularly; thus, the estate no longer treats the vines systematically with sulphates. Whenever possible, the fight against vine moths is carried out using mating disruption capsules, which means poison-based treatments are avoided.

Respect for traditional methods therefore remains crucial, all the while using modern means. By working in this way, we hope to preserve our precious terroir.

WORK IN THE CELLAR

Wine is a noble product and must not be mishandled.

La vinification au domaine

After consulting the various analyses carried out by the oenological laboratories just before harvesting, we carefully observe the maturation of the grapes in our vines by carrying out taste analyses and measurements of acidity and sugar.

We determine the harvest date and the order of harvesting the different plots according to the state of the grapes.

With the help of 25 pickers, we can start the harvest: the grapes are sorted in the vineyard to eliminate those that are not perfectly healthy or not ripe enough; the harvest is then brought back to the winery in boxes.

The fully renovated winery is equipped with open enamel vats and top-of-the-range stainless steel vats.

Wine is a noble product and must not be mishandled at any stage of its life: on the strength of this conviction, the estate has invested in equipment of the highest technological level in recent years.

First, the stainless steel destemmer with variable speed control is used to destem the bunches gently and gradually, without crushing the berries and causing them to burst.

Once filled, the vat is unified and cooled to a temperature of 9 °C using a heat exchanger: the cold pre-fermentation maceration phase lasts for about five to six days. The beginning of alcoholic fermentation then takes place naturally with indigenous yeasts, resulting in those sought-after flavours of the terroir.

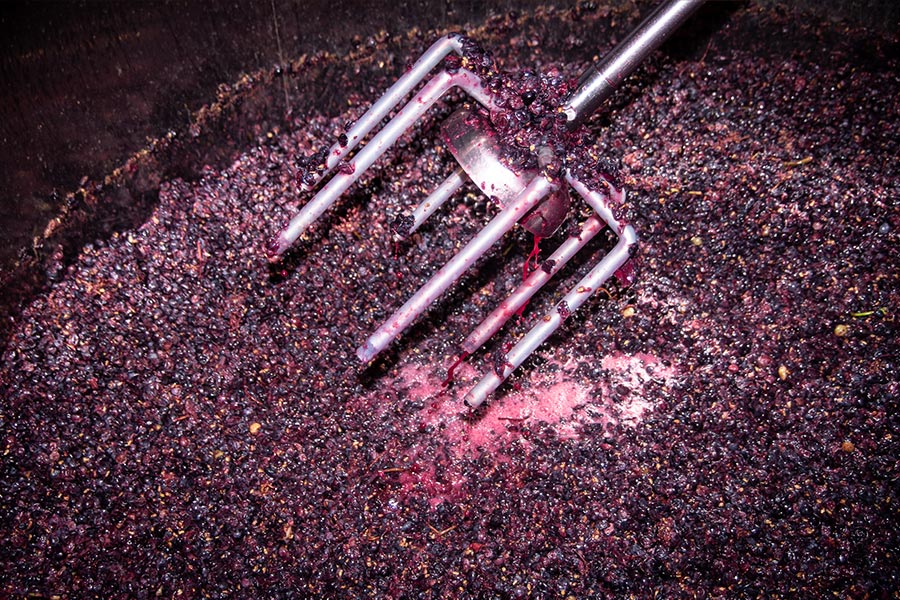

During the fermentation phase, punching down occurs twice daily, now facilitated by a modern pneumatic punching down line. Pumping over is also carried out at the end of fermentation, as well as rack and return.

Follow-up analyses are carried out daily; the temperature is carefully controlled so as not to exceed 32 °C during fermentation.

After about 15 days in the vat, depending on the cuvées and the vintage, the fermentation is complete. Then comes devatting when the must is sent to the press: we are now equipped with a pneumatic stainless steel system, which guarantees perfect quality – pressing is carried out gently at low pressure (compressed air in a flexible membrane).

After 24 to 36 hours of débourbage, the wines are sent using gravity to barrels in the cellar; depending on the cuvée, we use 20% to 50% new barrels from different forests (Allier, Limousin, Nièvre and Tronçais).

MATURATION OF OUR WINES

Once the vinification is finished, the wine maturation period begins, and lasts 15 to 18 months before bottling.

The technique of maturation on the lees in barrels gives greater organoleptic potential to the wines; the use of barrels, however, must be reasonable: the oak must be a means rather than an end.

The woody character should support and strengthen the wine, but not dominate it. Contact with the wood adds pleasant qualities when tasting, and a sweet vanilla scent. Above all, maturation in barrels means continuous moderate oxygenation can occur through the air that is believed to pass through the wood and certainly through the bunghole and the joints between the staves. There is also a dissolution of extractable compounds of the wood in the wine.

For good results, the wine put into the barrels must be balanced and rich enough in tannins and anthocyanins; otherwise it will show dryness and become lean. The trace left by the wood will be as discreet as the wine is rich and structured.

The barrels are topped up regularly to compensate for any loss due to evaporation. Throughout the maturation process, numerous tastings and analyses are carried out to follow the evolution of the wine. Racking is carried out, if necessary, after malolactic fermentation.

A blend of wines from new wood and wood that has seen two to five wines is made in stainless steel vats the day before bottling; the lees are thus separated from the wine. If the turbidity analysis is good, no filtration is carried out before bottling, preserving all the aromatic freshness of the wine. Otherwise, light kieselguhr filtration is carried out.

Bottling can then take place; this is generally planned for the beginning of spring, after consulting the lunar calendar, to avoid thermal shock. It is carried out using a mobile workshop with modern and efficient equipment. The bottles are then stacked in the cellar awaiting packaging, which takes place on the day before shipping.